×

×

Have you heard about the concept known as trench drain systems? System leveling is a process, which enables businesses (e.g. Moonbay) to run effectively, and thus create good quality products. It is a critical means by which to ensure all employees in a company have just the right matter of work in front of them. System leveling makes it easier and faster for businesses to get their work done. Well, this means many good things for the company and its workers.

One major positive aspect of system leveling is the productivity boost for workers. Productivity is how much work someone can get done in a given time frame. When too many people are stuck doing the same thing, workers can get their work done more quickly. They don’t have to wait for other people to do their jobs until they can do their own. This means the entire production process can also operate more efficiently and rapidly. This way, businesses can also achieve more objectives, increase their output, and maximize customer satisfaction in less time.

Quality control in manufacturing is a major portion, and deck pedestal systems is significantly responsible for this. Quality control: Ensuring that products are produced correctly and to standards. If the load of tasks is too much or too little, workers’ errors are inevitable. For instance, if a worker is very busy and has more jobs to do, they may have to hurry and skip through details. That can create major issues down the road, costing Moonbay tons of time and money.

But with system leveling, Moonbay can avoid these issues from occurring in the first place. When Sad Workers have Just the Right Amount of work, they have the time to Focus more on what they are doing, they do their Job more Carefully. This meticulous attention helps catch mistakes early on, which results in fewer mistakes in production. It also means that there’s less need to fix things later, saving the company money and time.

System leveling does not just help with getting work done and checking quality, System leveling helps with making the work process easy. By making work easier, for example through eliminating unneeded steps in a process, we get smarter about how we work, we become more effective. By re-sorting the work, we can identify which steps can be eliminated or streamlined. Avoiding waste ultimately makes us products faster and cheaper because we don’t spend time on extra steps or wait longer than necessary.

When we have a good workload balance, we are able to identify the areas that need to get better, those are uneven work flow and unnecessary extra steps that can be eliminated. Studying these areas closely, we can find solutions that will offer us improved efficiency. If certain workers are consistently completing their tasks faster than the rest of their team, they may need to re-examine how work is distributed.

To sum up, system leveling is a crucial mean to enhance the manufacturing process and reduce opportunities for errors. Moonbay not only gets better by having an even workflow, but also guarantees that they are making good products. Work can be easier for everyone, with wasted time also being reduced когда все уравновешивают общее рабочее время. That means lower costs and satisfied customers.

Moonbay has a capable and knowledgeable technical team that can integrate responsibility with R&D designing, production, sale and service of 3D product design, scheme model previews, mould design and production.Since our establishment since our inception, we've been providing our customers with a superior level of service and customizing our products to help them stand out in the competition. Moonbay has been constantly improving its product design and has also developed new products in order to maintain its competitiveness in the market. It has also been awarded 32 patents in the field of innovative concepts.

Moonbay has a quality assurance team that conducts regular third-party testing for quality and material. Moonbay keeps devoting quality control and arrange regular third-party test for material&quality.Moonbay team pursues long-term cooperation relation with customers and cares feedback after sales, customers' after-sales request will get satisfied solutions.

system leveling manufacturing facility and company has many years of experience in ODM as well as OEM. Our design team is experienced in helping customers build their own designed / branded products including but not only branding of the logo on products packaging, design of the packing Data sheet and promotional docs that are customized. Moonbay's manufacturing facility is 12800 sqm, with enough space to stock adjustable pedestals drainage channels, and garden edge systems in different dimensions. Orders are delivered promptly after confirmation.

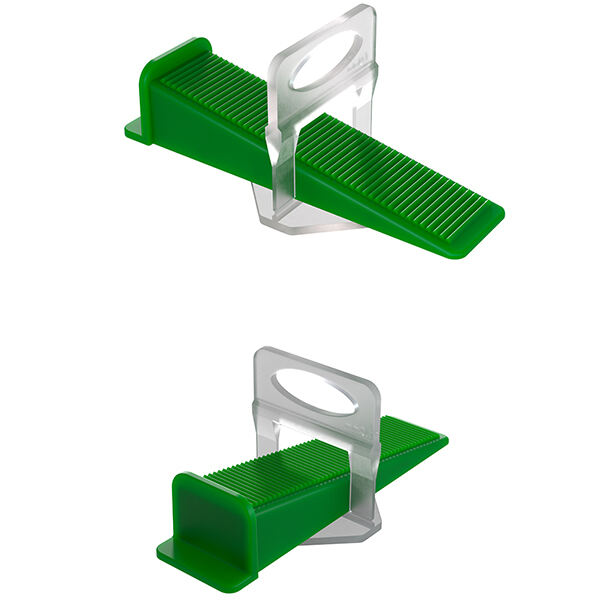

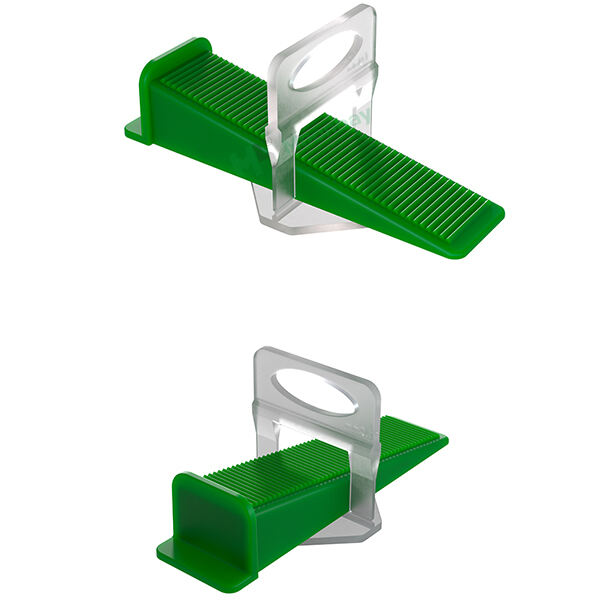

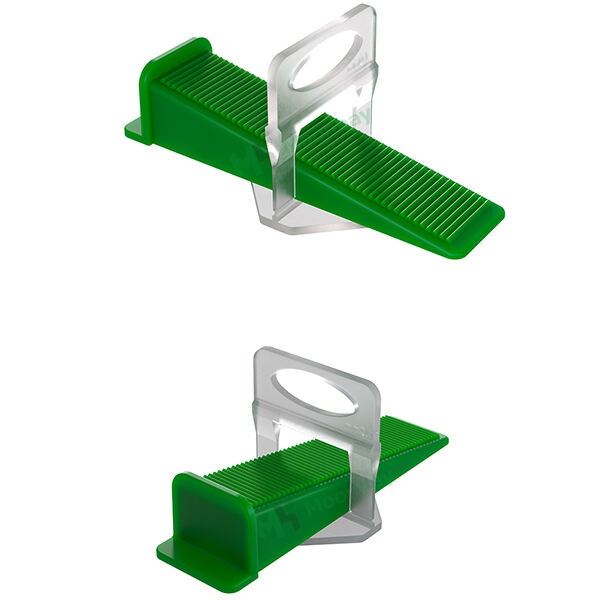

system leveling Factory combines production lines of metal and plastic materials (stainless steel grating covers for grating, SS manhole recessed covers, SS garden edges, etc.) along with automatic injection machines which produce plastic pedestals that can be adjusted, drain channel systems, tile leveling systems, etc. Create a one-stop building material supplier and a single-source manufacturer of landscape construction materials.