×

×

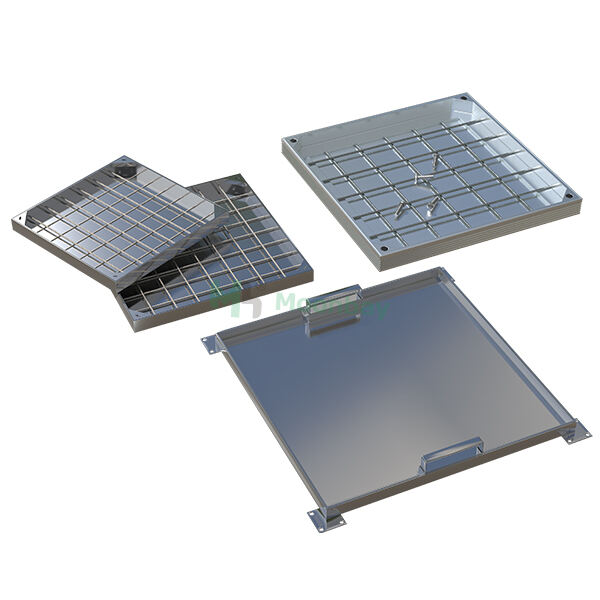

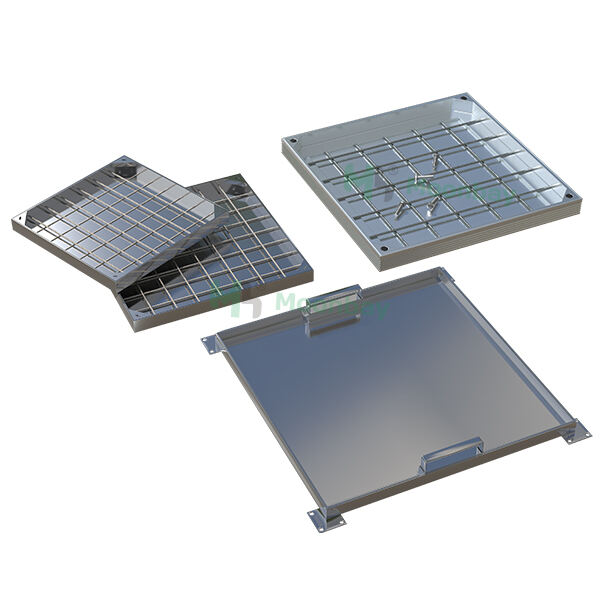

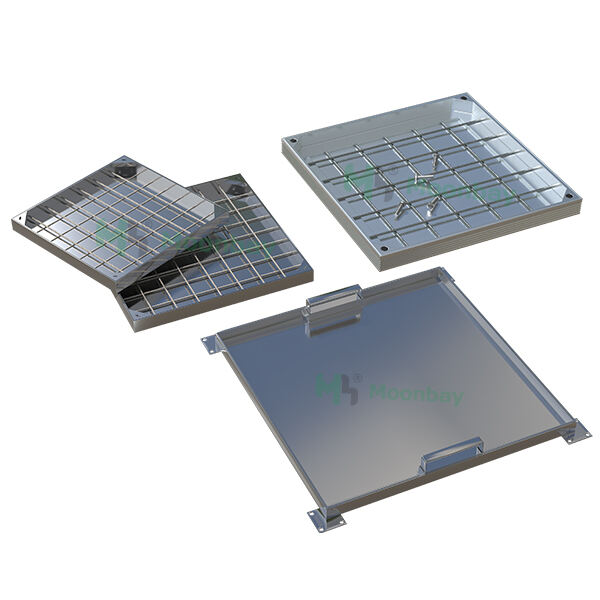

Manhole covers are square mainly so they don't fall through the hole that they're covering, but easier to make. Workers that create manhole covers usually start with large sheets of steel. These sheets allows us to cut square covers; relatively more easy and faster. This also saves cost since they can be manufactured at a higher speed. This also means that square covers are the most economical choice for cities and companies.

Square covers can cover larger holes than round covers, which is another big reason why they are used. This is quite useful as a lot of bigger pipes and drainage system needs hidden so that our streets are clean and safe. Moreover square covers are made in form that they stand on top of hole with more stablity. This makes it so that they have less chances of landing inside the hole that they are covering. This design aims to reduce the accidents and injuries of road users thus leaving our streets so much safer for everyone.

A circle, on the other hand, can fit in a hole but it can only remain static if it fits perfectly. If a circle can get inside if you non-oriented correctly, which is not very good. On the other hand, a square can be rotated at any angle and still pass through the hole. It proves to be very useful for the workers who have to frequently put on and remove the covers. It minimizes their workload and lets them work faster.

Square covers are more stable and less prone to movement, which means they can bear a larger load as compared to their round counterparts. Through this strength, they are more useful to be used at crowded areas or for such other areas where heavy machinery is being utilized like construction sites. That ability to withstand heavy weight means square covers can be trusted on keeping everyone safe.

Many argue that round covers are safer because they cannot fall in the hole they are covering. Fair enough, safety is paramount. According to some, round covers roll easier than square and may stand the potential for traveling during a handling accident away from those dealing the lid. And this debate carries on into an even wider circumference of scenarios.

A sink drain is much more than just a sign of the time; it requires quite a lot more work to create. It takes a lot of consideration from engineers and designers. They have to select the content which will be tough and last longer. They also have to factor in how large of a hole they plan on covering and how much weight it will need to support.

After the design is finalized, a cover is built and then fitted for installation. Climbing, installing a cover means carefully removing the old one out of the hole and putting in a new one in its place. It is a vital component of the job that needs to be done safely and correctly with Proper tools & training. A correctly installed unit helps to maintain safety for all who share the street.